Activities

Multidisciplinary

Design Engineering

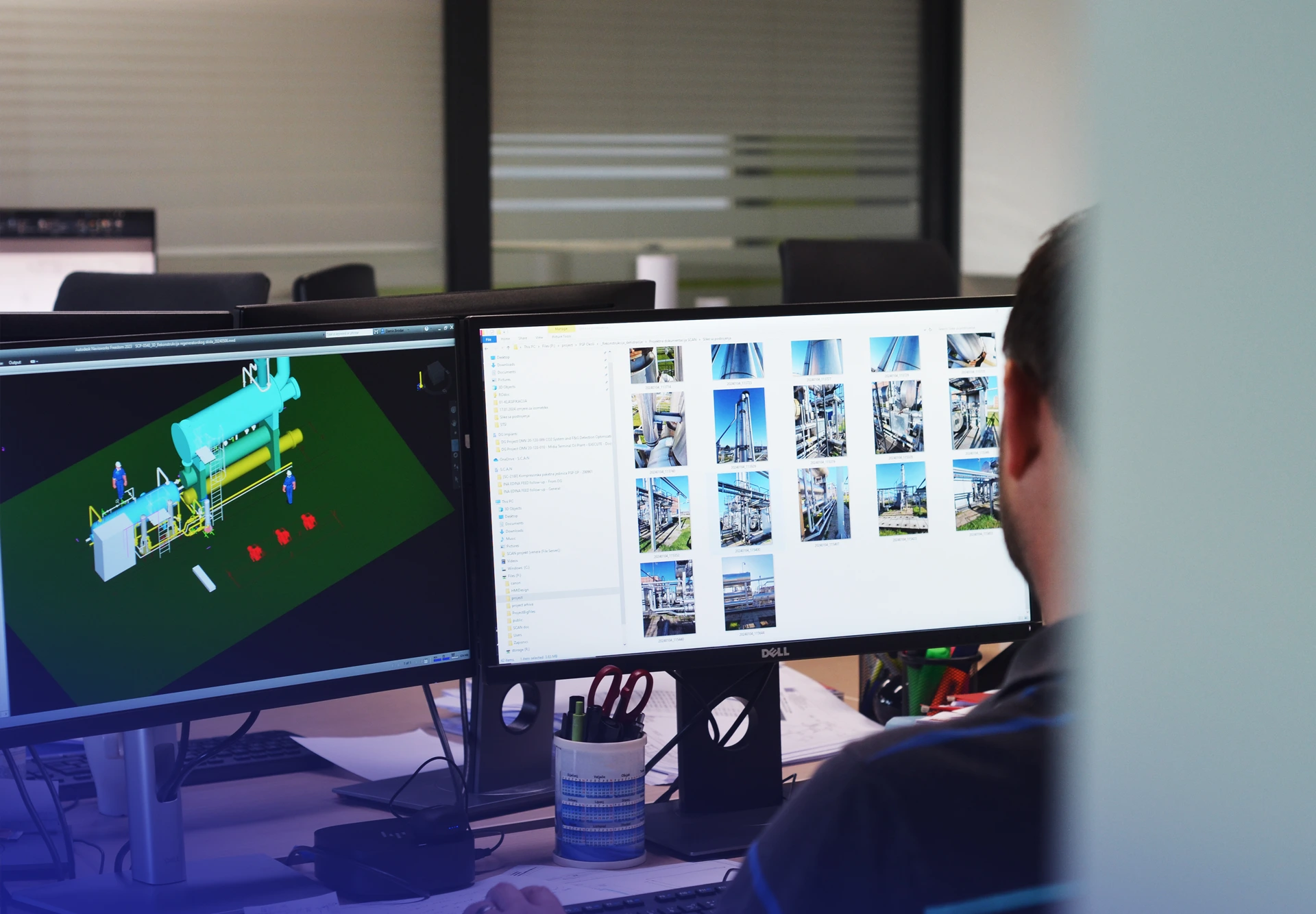

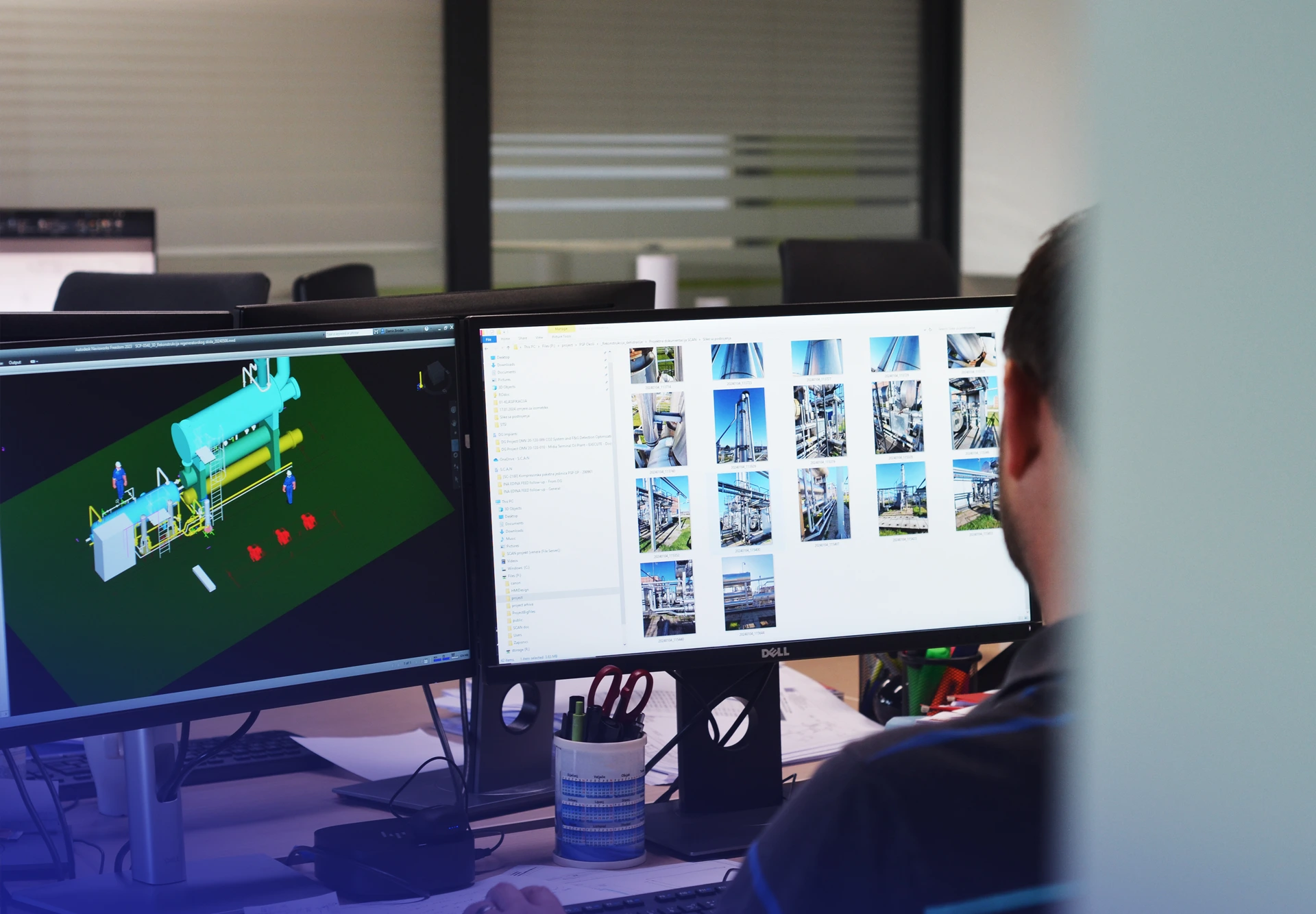

SCAN PROJEKT has established a strong and highly competent design engineering team, which can support our clients in all project phases, including feasibility studies, FEED, basic as well as detailed engineering. Having the engineers from SCAN systems integration and maintenance departments at hand, gives us also the possibility to receive valuable feedback from the field, further enhancing the quality of design solutions provided to our clients. This we see as a significant competitive advantage comparing to other companies specialized for design engineering only.

WITHIN THE ENGINEERING PROJECTS, SCAN PROJEKT FULLY FOLLOWS RECOMMENDATIONS FROM LATEST INDUSTRY STANDARDS.

Our engineers are equipped with most up-to-date software tools enabling us to efficiently perform required tasks. These include but are not limited to:

-

AutoCAD Plant Design Suite

-

AutoCAD Advanced Steel

-

Autodesk REVIT

-

Inventor Professional

-

CADWorx Plant Professional

-

Bently STaadT Pro Connect - structural analysis and design software

-

Autodesk Robot Structural Analysis Professional

-

Aspentech AspenONE (Hysys) - process simulation software

-

Schlumberger VMG Simmetry with Dynamics, Pipe and Flare – process simulation software

-

PV Elite Hexagon – pressure vessel design software

-

VVD Hexagon – pressure vessel design software

-

DNV Synergi Plant RBI Offshore – RBI software

-

ePlan Electric P8 Professional, with PPE (Process Plant Engineering) module

-

IHS PHAPro

-

Exida exSILentia

Process and Functional Safety Consultancy

Processes, especially those in oil&gas and chemical plants, involve major hazards with significant potential to cause human losses and harm to assets or environment. Safety Instrumented Systems (SIS) play a significant role within the process industry as their purpose is to reduce the risk of these hazards to a tolerable level.

Through the years of experience in design and implementation of safety instrumented systems, as well as by continuous education of our specialists, we have gained expertise which we can share with our clients by providing the assistance in this demanding and nowadays critical discipline.

In addition to providing safety instrumented systems design according to IEC 61511 standard, our process and functional safety specialists can offer you the following services:

-

Leading of Risk Assessment studies (HAZID, HAZOP, QRA…)

-

Leading of SIL classification studies (applying Risk Graph or LOPA methods)

-

SIL verification

-

Preparation of Safety Requirements Specifications

-

Preparation of Reports on Major Hazards

-

Preparation of other safety studies

-

TÜV Rheinland certified Functional Safety trainings (in cooperation with TVC Dubai and TÜV Rheinland)

-

Custom, tailor made safety trainings

Hazard and operability studies for process plants

The Hazard and Operability (HAZOP) study is the most widely used Process Hazards Analysis (PHA) technique in the chemical, pharmaceutical, oil and gas, nuclear, and other process industries worldwide. HAZOP is used during the design stages of a new process or project, for major process modifications, and for periodic review of existing operations. Many regulators around the world, recognizes the HAZOP technique as an acceptable methodology for evaluating risk.

HAZOP is a structured and systematic examination of a process or operation in order to identify and evaluate problems that may represent risks to personnel, the environment or equipment, or prevent efficient operation. The analysis session, which involves a multidisciplinary team, is aimed at identifying potential deviations from expected conditions, analysing their possible causes in every single part of the system.

HAZOP is a structured and systematic examination of a process or operation in order to identify and evaluate problems that may represent risks to personnel, the environment or equipment, or prevent efficient operation. The analysis session, which involves a multidisciplinary team, is aimed at identifying potential deviations from expected conditions, analysing their possible causes in every single part of the system.

SIL ASSESSMENT (IEC 61508/61511) AND VERIFICATION

The need to improve reliability, the increasing failure tolerance and the standardization of technical safety systems led to the development of the SIL concept. The acronym stands for Safety Integrity Level, which represents the level of risk reduction required by a safety instrumented function within the implementation of a Safety Instrumented System (SIS) for a specific process. Practically, the SIL identifies the integrity level that must be associated to safety instrumented functions (SIF), according to the specific risk of the system. The SIL assessment is a systematic analysis developed by a team of professionals and based on risk: it identifies the integrity requirements for every safety function.

The SIL VERIFICATION consists in applying specific mathematical models to verify the PFD (Probability of Failure on Demand) of the safety function, to make sure that it meets the specific integrity requirements

The SIL VERIFICATION consists in applying specific mathematical models to verify the PFD (Probability of Failure on Demand) of the safety function, to make sure that it meets the specific integrity requirements

Engineering and construction follow-up and supervision

We provide comprehensive engineering and construction follow-up services, tailored to the needs of our Clients. Our experience and competences in engineering and projects execution ensure projects are executed with precision, safety and efficiency.

From engineering design validation and procurement follow-up to construction supervision and commissioning support, we work closely with our clients to ensure seamless project delivery, compliance to Clients and industry standards and long-term operational reliability.